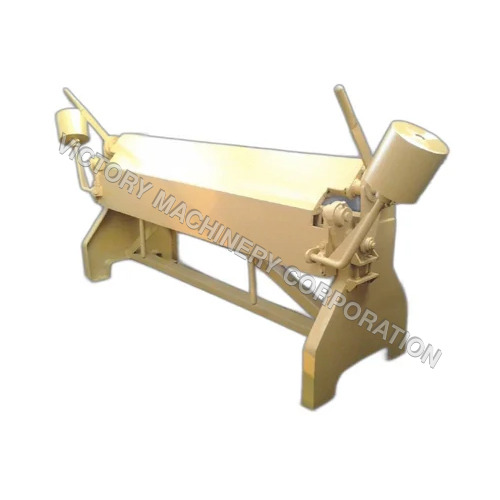

Hydraulic Press Break Machine

Price 53000 INR/ Piece

MOQ : 1 Piece

Hydraulic Press Break Machine Specification

- Cooling System

- Oil Cooling

- Machine Type

- Hydraulic Press Brake

- Drive

- Hydraulic Drive

- Voltage

- 415 V

- Motor Power

- 7.5 HP

- Lubricating System

- Centralized Lubrication

- Power Rating

- 7.5 kW

- Production Capacity

- 15-20 units/month

- Frequency

- 50 Hz

- Accuracy

- 0.1 mm

- Operating Temperature

- 5C to 40C

- Model No

- PB160

- Features

- High bending accuracy, robust construction, overload protection

- Noise Level

- 75 dB

- Control System

- Manual/NC Controller

- Frame Type

- Welded Steel Frame

- Product Type

- Press Brake Machine

- Technology

- Hydraulic Technology

- Power Source

- Hydraulic

- Operating Type

- Semi-Automatic

- Power

- 7.5 kW

- Pressure

- 160 Ton

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 3200 x 1800 x 2000 mm

- Weight (kg)

- 2500 kg

- Color

- Blue/Grey

- Usage & Applications

- Sheet metal bending, forming operations

- Standard Accessories

- Tool set, foot pedal

- Throat Depth

- 350 mm

- Back Gauge Range

- 600 mm

- Hydraulic Oil Type

- ISO VG 46

- Pump Type

- Gear pump

- Cycle Time

- 18 seconds

- Oil Tank Capacity

- 200 liters

- Safety Features

- Emergency stop, overload relay

- Main Cylinder Diameter

- 100 mm

- Electric System

- Three Phase

- Ram Stroke

- 120 mm

- Table Width

- 80 mm

- Max Bending Length

- 2500 mm

- Operating Pressure

- 180 bar

Hydraulic Press Break Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

About Hydraulic Press Break Machine

Select the praiseworthy PB160 Hydraulic Press Break Machine-a formidable new release designed for sheet metal bending and forming operations. In demand across industries, this machine boasts an astounding bending length of 2500 mm, throat depth of 350 mm, and a remarkable 160-ton pressure, supported by robust hydraulic technology. With a three-phase electric system, gear pump, and advanced safety features including overload relay and emergency stop, it exemplifies reliability. Powder coated with a welded steel frame, it delivers high bending accuracy (0.1 mm) while remaining energy efficient and easy to operate.

Applications, Features, and Usage Type of Hydraulic Press Break Machine

The PB160 Hydraulic Press Break Machine is ideally implemented in fabrication workshops, industrial manufacturing units, and sheet metal processing plants. Its notable features include high bending accuracy, central lubrication, and overload protection, making it a preferred choice for robust forming operations. The semi-automatic operating type, along with manual or NC controller options, ensures versatility in usage. Its powerful hydraulic drive and welded steel frame support demanding workflow needs, delivering precision and reliability in metalworking tasks.

Supply Ability, Delivery Time, and Sample Policy of Hydraulic Press Break Machine

With a supply capacity of 15-20 units per month, the PB160 Hydraulic Press Break Machine is efficiently fulfilled upon Purchase Order confirmation. Order completion is managed with adherence to customer timelines, ensuring prompt delivery anywhere in India. Sample policy is available for prospective buyers to evaluate the machine before making larger investments. Each unit is sourced directly from manufacturer, supplier, or authorized distributor to guarantee authenticity and performance quality throughout the supply chain.

Applications, Features, and Usage Type of Hydraulic Press Break Machine

The PB160 Hydraulic Press Break Machine is ideally implemented in fabrication workshops, industrial manufacturing units, and sheet metal processing plants. Its notable features include high bending accuracy, central lubrication, and overload protection, making it a preferred choice for robust forming operations. The semi-automatic operating type, along with manual or NC controller options, ensures versatility in usage. Its powerful hydraulic drive and welded steel frame support demanding workflow needs, delivering precision and reliability in metalworking tasks.

Supply Ability, Delivery Time, and Sample Policy of Hydraulic Press Break Machine

With a supply capacity of 15-20 units per month, the PB160 Hydraulic Press Break Machine is efficiently fulfilled upon Purchase Order confirmation. Order completion is managed with adherence to customer timelines, ensuring prompt delivery anywhere in India. Sample policy is available for prospective buyers to evaluate the machine before making larger investments. Each unit is sourced directly from manufacturer, supplier, or authorized distributor to guarantee authenticity and performance quality throughout the supply chain.

FAQ's of Hydraulic Press Break Machine:

Q: How does the Hydraulic Press Break Machine benefit sheet metal operations?

A: The machine offers precise and consistent bending, forming, and shaping of sheet metal, increasing productivity and minimizing errors due to its high bending accuracy of 0.1 mm.Q: What are the safety features included in the PB160 Hydraulic Press Break Machine?

A: The PB160 is equipped with emergency stop, overload relay, and robust construction to ensure operator protection and machine safety during all operational procedures.Q: Where is the Hydraulic Press Break Machine typically used?

A: It is frequently deployed in fabrication units, factories, and industrial workshops requiring efficient metal shaping and forming solutions for various manufacturing tasks.Q: What is the process for placing a purchase order and receiving the machine?

A: Buyers can place purchase orders through authorized suppliers or distributors, and delivery is completed promptly with supply capability of 15-20 units per month across India.Q: How accurate is the Hydraulic Press Break Machine during operation?

A: The machine delivers a high bending accuracy of 0.1 mm, ensuring dependable and precise results in sheet metal bending activities.Q: When should sample evaluation be considered for the PB160 Model?

A: Sample evaluation is recommended before large-scale purchases so potential buyers can verify performance and suitability for their specific metalworking requirements.Q: What type of hydraulic oil and cooling system does the machine use?

A: The PB160 uses ISO VG 46 hydraulic oil and features an oil cooling system to maintain optimal operating temperatures during prolonged usage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Press Break Category

Hydraulic Press Break Machine

Price 900000 INR / Piece

Minimum Order Quantity : 2 Pieces

Usage & Applications : Industrial

Warranty : 1 Year

Color : Blue

Operating Type : Automatic

Hand Operated Trunk Folding Machine

Price 55000 INR / Piece

Usage & Applications : Metal trunk folding

Warranty : Depends on the manufacturer

Color : Blue & White

Hand Operated Manual Sheet Bending Machine

Price 90000 INR / Piece

Minimum Order Quantity : 2 Pieces

Usage & Applications : Industrial

Warranty : 1 Year

Operating Type : Automatic

Hand Operated manual Sheet Bending Machine

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free