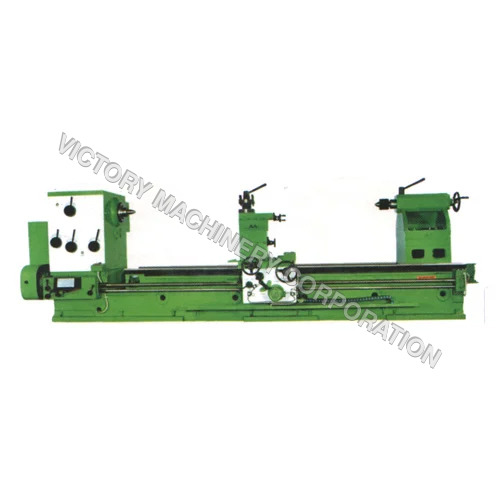

Light Duty Lathe Machine

Price 80000 INR/ Piece

Light Duty Lathe Machine Specification

- Product Type

- Light Duty Lathe Machine

- Material

- Cast Iron Structure

- Cutting Thickness

- Up to 10 mm

- Cutting Speed

- 25 to 35 meter/min

- CNC Or Not

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Max. Swing Diameter

- 250 mm

- Voltage

- 220 V

- Weight (kg)

- 350 kg

- Dimension (L*W*H)

- 1500 x 500 x 800 mm

- Capacity

- Standard

- Feature

- High Precision, Durable

- Color

- Blue-Grey

- Bed Width

- 200 mm

- Headstock Spindle Nose

- MT-3

- Number of Speeds

- 8

- Spindle Bore

- 38 mm

- Chuck Size

- 150 mm

- Surface Finish

- Ground Finish

- Tailstock Quill Travel

- 110 mm

- Application

- General Metal Turning, Facing, Drilling, Parting and Threading Operations

- Motor Power

- 1.0 - 1.5 HP

- Lead Screw Diameter

- 25 mm

- Distance Between Centers

- 500 mm

- Phase

- Single/Three Phase

- Tool Post Type

- 4-Way

About Light Duty Lathe Machine

Product Specification

| Model | RXZ |

| Height Of Centre | 175mm |

| Width Of Bed | 240mm |

| Max.Swing Over Bed | 350mm |

| Max.Swing Over Side | 190mm |

| Bore | 40mm |

| Nose | 6-TPI |

| Speed - 8 (R.P.M) | 45 -900 |

| Cross Side | 240mm |

| Lead Screw TPI | 4 TPI |

| Tail Stock Sleeve | MT-3 |

| Power Required | 1.5 H.P |

Precision Machining Made Easy

Engineered for high-precision results, this light duty lathe machine is designed for small to medium scale applications including metal turning, drilling, facing, parting, and threading. With an easy-to-operate manual control system and a maximum swing diameter of 250 mm, users enjoy enhanced control and accuracy on every project.

Durable Construction for Longevity

The lathes bed and structural components are crafted from robust cast iron, ensuring stability and reduced vibration during operation. Its ground surface finish enhances precision, while the machines ergonomic dimensions and semi-automatic features contribute to user safety and convenience.

FAQs of Light Duty Lathe Machine:

Q: How can I use this light duty lathe machine for general metalworking operations?

A: This lathe machine is designed specifically for general metal turning, facing, drilling, parting, and threading. Simply secure your workpiece between centers, select the appropriate speed from the 8 available, and use the 4-way tool post to perform your desired machining operation all under manual control.Q: What materials can the lathe machine handle efficiently?

A: The machine is ideal for most common metals typically used in workshops, including mild steel, brass, aluminum, and similar materials, with a cutting thickness of up to 10 mm. Its robust cast iron structure ensures stable and precise machining for standard shop requirements.Q: When is it beneficial to choose a manual, light duty lathe over a CNC system?

A: A manual, light duty lathe is practical for small batch production, prototyping, repair jobs, or where hands-on control and adjustments are needed frequently. Its cost-effective for operations not requiring automation and perfect for users prioritizing high precision and flexibility.Q: Where can this lathe machine be installed and operated?

A: Due to its compact size (1500 x 500 x 800 mm) and moderate weight (350 kg), this machine is suitable for small workshops, educational institutions, tool rooms, and light manufacturing units. It can operate on either single- or three-phase 220 V supply, making it versatile for various settings.Q: What is the process for changing speeds on this lathe?

A: Speed changes are accomplished manually, allowing you to select from 8 available speeds depending on your material and the required operation. Refer to the machines speed chart to choose the optimal setting for each machining task.Q: How does this lathes cast iron structure benefit users?

A: The cast iron structure minimizes vibration and increases stability, leading to superior surface finish and consistent dimensional accuracy of machined parts. It also greatly enhances the machines durability, ensuring long-term performance even under regular use.Q: What are the main advantages of the 4-way tool post feature?

A: The 4-way tool post allows rapid tool changes and efficient multi-tool setups, making the machining process more productive by reducing downtime and improving workflow flexibility. This is particularly valuable in small batch production or jobs requiring frequent tool changes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Extra Heavy Duty Lathe Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Other, SemiAutomatic

Color : Industrial Green/Grey

Control System : Other, Manual

Voltage : 415 V

Extra Heavy Duty Roll Turning Lathe Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Other, Manual

Color : Industrial Grey/Blue (customizable)

Control System : Other, Manual Control, Electrical Panel Controls

Voltage : 415 V, 3 Phase, 50 Hz

Medium Duty Lathe Machine

Price 130000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Color : Blue

Control System : PLC Control

Voltage : 220 Volt (v)

All Geared Extra Heavy Duty Lathe Machine

Price 600000 INR / Piece

Minimum Order Quantity : 2 Pieces

Automatic Grade : Automatic

Color : Green

Control System : PLC Control

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS